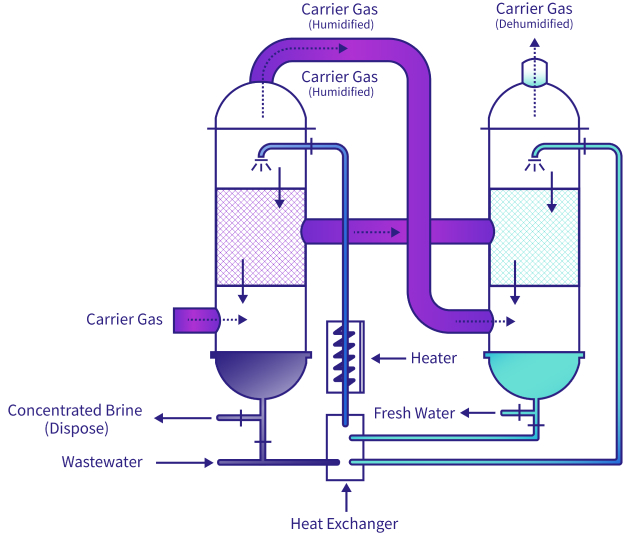

Carrier Gas Extraction (CGE)

Nature’s Rain Cycle. Optimized.

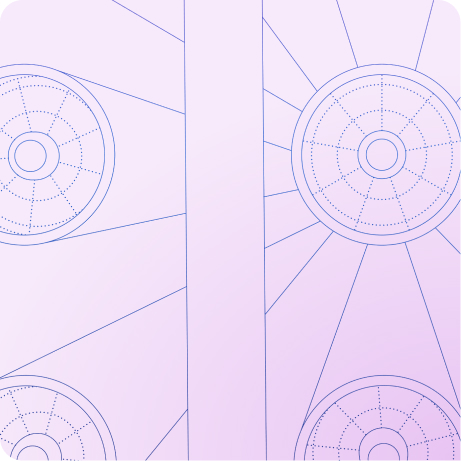

Our award-winning patented Carrier Gas Extraction (CGE) thermal evaporators go above and beyond traditional evaporative techniques incorporating patented technologies such as novel bubble columns, packed bed, and thermodynamic balancing. The use of carrier gas mimics nature’s rain cycle to humidify and dehumidify at the lowest total water cost.

Achieve MLD & ZLD at the Lowest Total Water Cost

The patented design minimizes fouling and scaling to maximize system reliability and availability. The CGE technology is suitable for highly fouling and scaling wastewaters with high TDS that are challenging or costly to treat with reverse osmosis systems. High saline and contaminated wastewaters and brine are converted into pure freshwater at brine concentrations to the saturation limits of salt (TDS up to 260,000 mg/L NaCl). This minimizes the required capacity of downstream ZLD systems resulting in typical cost savings of more than 50% in CAPEX, OPEX, and Total Water Costs compared to conventional thermal technologies.

Benefits of Carrier gas extraction

Lower CAPEX and OPEX

CGE saves our clients money. Typical savings of 65% lower capital costs (CAPEX) and 35% lower annual operating costs (OPEX).

Sustainable and Efficient Energy Consumption

Smart design and engineering of CGE make your waste minimization ZLD operations more sustainable and energy-efficient.

System Reliability and Availability

CGE operates at low pressure and temperatures, which allows for higher reliability and site safety, and lower costs in materials of construction.

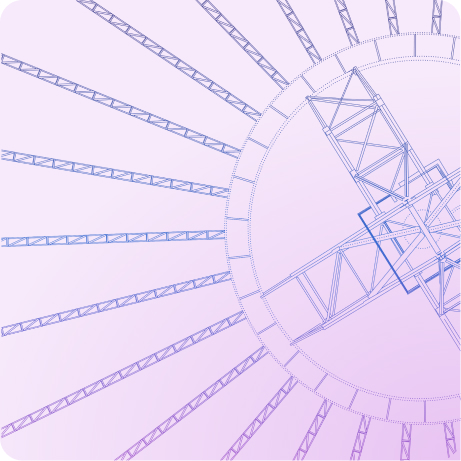

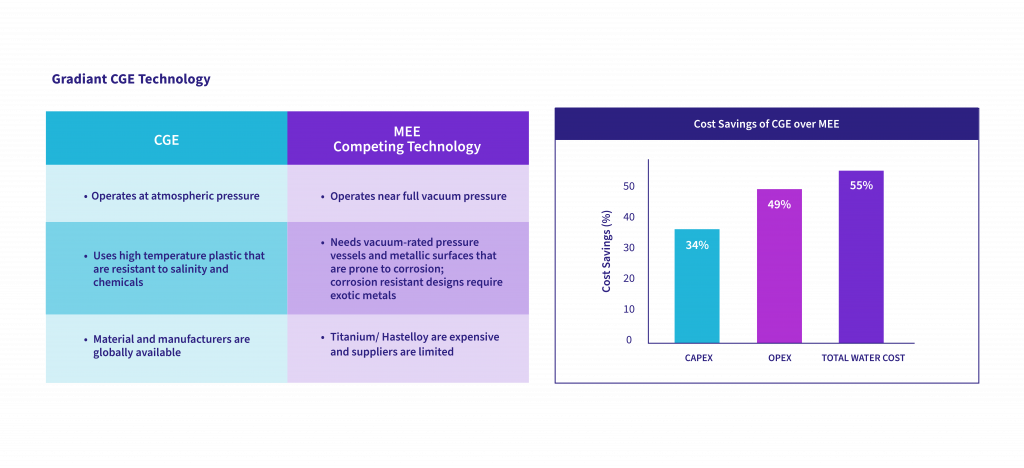

Gradiant’s CGE Technology

Gradiant’s CGE technology compared to conventional Multi-Effect Evaporation

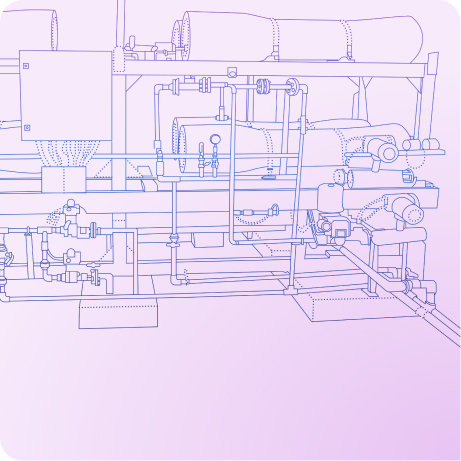

CGE technology at a Zero Liquid Discharge

facility in Singapore

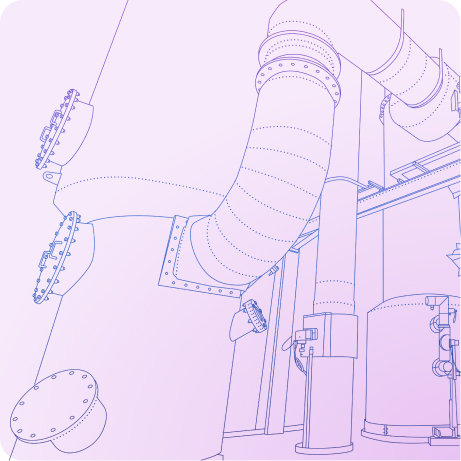

CGE Technology at a water treatment facility in the USA