Semiconductors

HIGH RECOVERY SEMICON LS RECLAIM (LSR) POWERED BY AI IN A LIMITED SPACE

Only Gradiant could deliver a high-recovery local scrubber reclaim (LSR) system, achieving 90% recycling rates, integrated with machine-learning AI to meet semiconductor manufacturers’ sustainability drivers. A custom-designed RO Infinity system, limited by available footprint at the existing facility, was delivered to treat the high variability wastewater for reuse in an LSR application. The facility is powered by SmartOps Digital for fully-optimized and fully automated operations.

Fast Facts

Location: Singapore

End User: Leading US Semiconductor

Manufacturer

Solution: Industrial Wastewater

& Recycling

Industry: Microelectronics

Feedwater Source: Local Scrubber Wastewater

Technology: RO Infinity, SmartOps AI

System Configuration:

4 x Ultrafiltration, 5 x RO Infinity

System Capacity: 9,600 m³/day

System Recovery: > 88%

Online Date: December 2022

Delivery Model: Design-Build (DB)

The Challenge

Gradiant worked with a global leader in design, engineering, and delivery of facilities for high-tech industries, to deliver an industrial water & recycling solution for a U.S. semiconductor company, one of the top manufacturers in the world. The end-user’s semiconductor fabrication plant in Singapore produces large volumes of local scrubber wastewater with high levels of TSS, organics, silica, and fluoride. They sought a LSR solution to treat and reclaim the wastewater for recycling and reuse through their manufacturing operations – this would bring sustainability into their operations by reducing the need for freshwater withdrawals and the amount of wastewater generated by the facility. With limited available footprint for the LSR system and the need for high-recovery recycling rates, a completely custom solution was needed to meet operational and sustainability targets.

The Solution

Gradiant delivered a custom-engineered RO Infinity system to achieve 90% system recovery rates. The LSR system was delivered as a design-build project over a fast-track schedule of 12 months from contract award to commissioning.

The RO Infinity system is fed by local scrubber wastewater at highly variable flows and concentrations, which is then transformed into fresh water that is recycled and reused for semiconductor fabrication. The system produces 9,600 m3/day of fresh water. There was extremely limited available footprint at the existing site, where the compact form factor of the RO Infinity technology allowed design and construction within a tight space.

The system is powered by Gradiant’s SmartOps Digital, an integrated platform for plant performance optimization and asset management. The efficiency and productivity of the LSR system is improved with machine-learning AI by identifying areas needing attention and proactively predicting the likelihood of future events – such as the need for membrane cleanings.

The Benefits

This tailor-made RO Infinity with SmartOps solution is fully optimized, fully automated, and only made possible by Gradiant. The system was able effectively to treat a high volume of Local Scrubber influent wastewater with an overall higher recovery (>80%) for re-use as LSR makeup water in their manufacturing facility as a part of their sustainability goals.

With Gradiant’s solution, the semiconductor manufacturer was able to leverage machine learning to effectively treat a complex wastewater stream and meet strict performance standards.

Impact Stats

90%

Reduction in Freshwater Withdrawal

90%

Reduction in Wastewater Generated

12

Months from Contract Award to Commissioning

9,600

m³ of Freshwater Generated Every Day

30%

Up to 30% Operational Cost Savings Compared to Conventional Technologies

Figures & Images

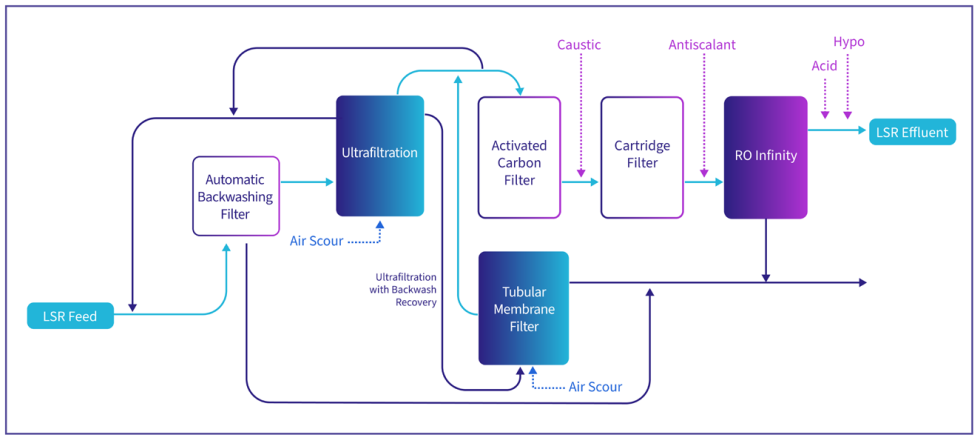

Semiconductor Manufacturer’s LSR Process Flow Diagram

Legal Disclaimer

This document is for general information only. No warranty or guarantee whatsoever is given or implied and Gradiant is not bound by or liable for or by the information contained herein. Customer has the sole responsibility to determine whether the information in this document are appropriate for Customer’s use, including without limitation actual site, geographical, and plant conditions, specifications, requirements, disposal, applicable laws and regulations. This document is the intellectual property of Gradiant, including but not limited to any patent or trademark contained in this document. Distribution of this document is not and does not imply any transfer of Gradiant’s intellectual property.

Gradiant, the Gradiant logo, and all trade and service marks denoted with ™ and ® are owned by Gradiant Corporation unless otherwise noted. ©2023 Gradiant.