Renewable Energy

RECOVERING WASTEWATER AND DOUBLING CAPACITY FOR SOLAR PV MANUFACTURING

Solar photovoltaic (PV) cells are rapidly becoming a more prominent and critical part of our renewable energy future. Gradiant works closely with industry-leading manufacturers to solve their water and wastewater challenges, innovating novel solutions, optimizing capital scope, and minimizing operational costs. A global manufacturer in India partnered with Gradiant to meet discharge requirements and sustainability goals for water reuse.

Fast Facts

Location: Gujarat, India

End User: One of India’s leading Solar PV manufacturers

Solution: Industrial Wastewater & Recycling

Industry: Renewable Energy

Feedwater Source: Rinse and Concentrated Process Streams

Technologies: Selective Contaminant

Extraction (SCE), RO Inifinity

System Capacity: 4,000 m3/day

Commissioning: 2023

Delivery Model: Design-Build (DB)

The Challenge

Solar PV manufacturing generates a highly complex matrix of chemical constituents in its wastewater, including total suspended solids, silica, fluorides, and other dissolved solids. One of India’s leading Solar PV manufacturers needed to address specific contaminants in their rinse and concentrated process streams — and sought Gradiant’s assistance. The solution would need to meet stringent requirements for marine discharge (particularly fluoride) and increased water recycling rates.

The Solution

Fortunately, Gradiant has expertise in treating challenging wastewater streams with the same contaminants. Gradiant had developed similar solutions for semiconductor and other solar PV manufacturers, mitigating both technical and schedule risks for the client.

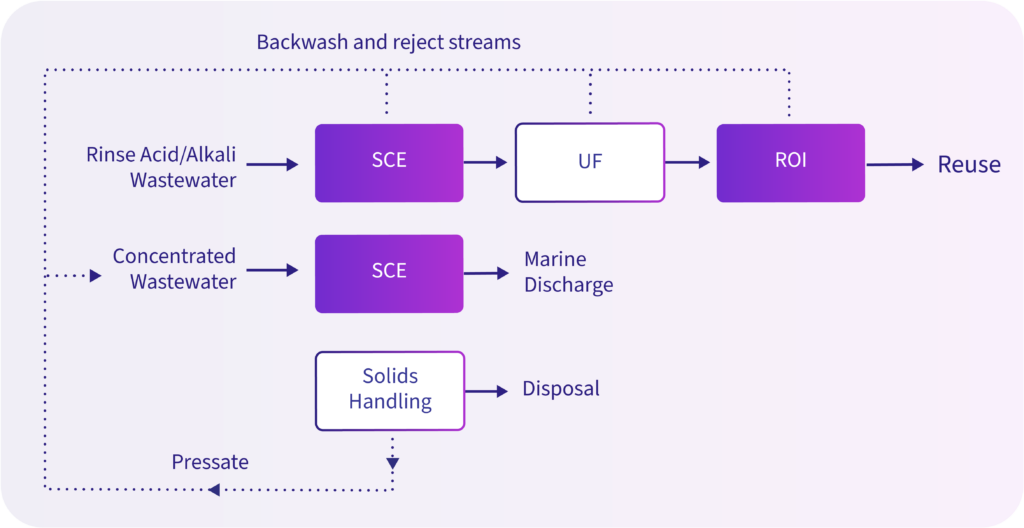

Gradiant designed a multi-step process leveraging Selective Contaminant Extraction technologies for rinse process stream treatment and pre-treatment for reuse. A two-stage high-rate solids recovery contact clarifier (HRSCC) reduces fluoride concentrations, while ultrafiltration (UF) removes additional suspended solids to meet pre-treatment requirements for downstream reverse osmosis (RO) operations.

RO Infinity further treats the combined waste streams to allow for the removal of dissolved solids, which then meets the process requirements for reuse.

Backwash, reject, and filter waste streams were combined in a concentrated wastewater treatment process to meet requirements for marine discharge. Solids waste handling systems then further treat waste solids for off-site disposal.

The Benefits

This project enabled the integrated site to double its capacity to help achieve India’s goal of achieving 500 GW of non-fossil fuel capacity by 2030. The innovative design of the 4 MLD wastewater treatment and reuse facility will also recover up to 75% of the wastewater, a feat that could not be achieved by other process schemes.

Gradiant is also working with the client to increase wastewater treatment and reuse capacity at the site, enabling the client to further expand their production processes 2X to 3X by 2027.

Impact Stats

4 GW

Vertically Integrated Solar PV cell and Module Manufacturing

2X

Plant Capacity Increase

4 MLD

Total Treatment Capacity

75%

Up to 75% Recovery of Wastewater

Figures & Images

Legal Disclaimer

This document is for general information only. No warranty or guarantee whatsoever is given or implied and Gradiant is not bound by or liable for or by the information contained herein. Customer has the sole responsibility to determine whether the information in this document are appropriate for Customer’s use, including without limitation actual site, geographical, and plant conditions, specifications, requirements, disposal, applicable laws and regulations. This document is the intellectual property of Gradiant, including but not limited to any patent or trademark contained in this document. Distribution of this document is not and does not imply any transfer of Gradiant’s intellectual property.

Gradiant, the Gradiant Logo, and all service marks denoted with ™ or ® are owned by affiliates of Gradiant Corporation unless otherwise noted. © 2024 Gradiant.