Renewable Energy

EMPOWERING SOLAR CELL MANUFACTURING WITH SUSTAINABLE WATER SOLUTIONS

Solar photovoltaic cells are rapidly becoming a more prominent and critical part of our renewable energy future. Gradiant works closely with industry-leading manufacturers to solve their water and wastewater challenges, innovating novel solutions, optimizing capital scope, and minimizing operational costs.

Fast Facts

Location: Tamil Nadu, India

End User: One of India’s largest companies’ Solar PV

Manufacturing business

Solution: Industrial Wastewater & Recycling

Industry: Renewable Energy

Feedwater Source: Process Wastewater

Technology: ROI, Selective Contaminant Extraction (SCE), CURE Chemicals

System Capacity: 8,100 m3 /day

Commissioning: 2024

Delivery Model: Design-Build, Commissioning, Operate & Maintain (O&M)

The Challenge

The Solution

Gradiant is delivering a high recovery RO Infinity (ROI) system, and pretreatment and ultrafiltration (UF) to the client for an industrial wastewater and recycling solution. The integrated facility will treat the complicated wastewater streams from solar PV manufacturing to allow for recycling and reuse in their upstream processes, helping our client minimize their water footprint and meet sustainability goals.

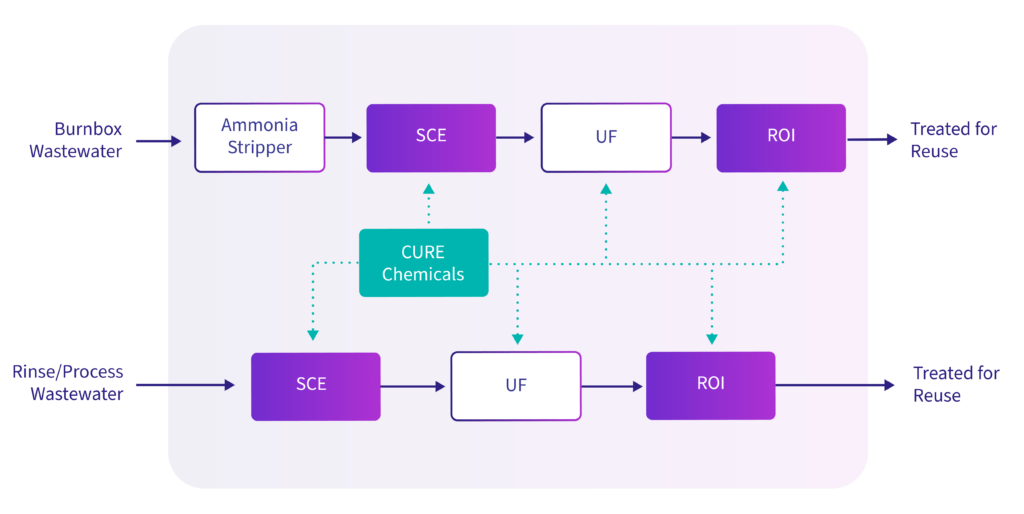

Gradiant created two flowsheets for the process and burnbox effluent streams, combining selective contaminant extraction (SCE) and RO Inifinty (ROI) technologies for both ammonia and fluoride removal, as well as treating water that is reused on-site. Gradiant is also providing chemicals and O&M services to ensure consistent and reliable operations.

The Benefits

By taking a value engineering approach early in the project, the Gradiant team was able to fast-track a viable solution for the customer. The client recognized this was a significant feat given the complex waste streams and a compressed project timeframe, which could only have been achieved through simplifying startup, commissioning, and ongoing operations for the client as part of an integrated solution.

The ROI system will recover up to 85% of the wastewater for on-site use and achieve ZLD limits. The future-proofed design will also increase plant capacity as the customer innovates new products and creates additional waste streams.

Impact Stats

4GW

PV Cell & Module Manufacturing

Facility

85%

Up to 85% Recovery of wastewater for beneficial reuse on-site

6,885

Up to 6,885 m3/day in freshwater

savings

71,500

Metric tons CO2 offset from PV

cells & modules

Figures & Images

Operation and Maintenace Process Flow Diagram

Legal Disclaimer

This document is for general information only. No warranty or guarantee whatsoever is given or implied and Gradiant is not bound by or liable for or by the information contained herein. Customer has the sole responsibility to determine whether the information in this document are appropriate for Customer’s use, including without limitation actual site, geographical, and plant conditions, specifications, requirements, disposal, applicable laws and regulations. This document is the intellectual property of Gradiant, including but not limited to any patent or trademark contained in this document. Distribution of this document is not and does not imply any transfer of Gradiant’s intellectual property.

Gradiant, the Gradiant Logo, and all service marks denoted with ™ or ® are owned by affiliates of Gradiant Corporation unless otherwise noted. © 2024 Gradiant.