Refining & Chemicals

SUSTAINABLE AND COST-EFFECTIVE MLD SOLUTIONS FOR DYE MANUFACTURING

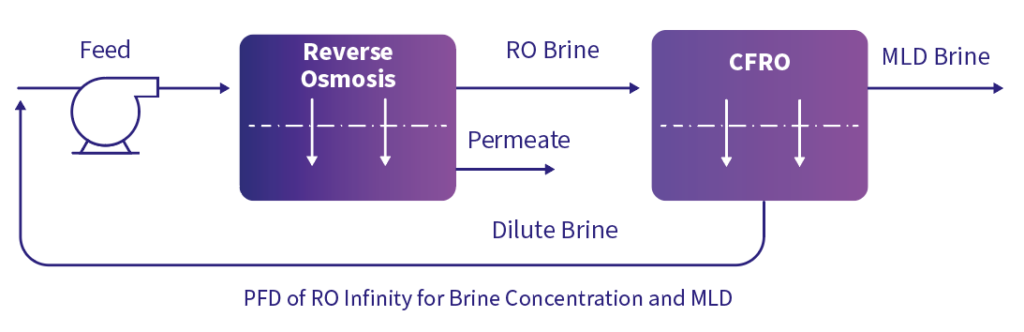

A Swiss-based global diversified provider of specialty chemicals and performance textiles, was in need of a sustainable and cost-effective solution to treat its dye wastewater. Gradiant answered with a Minimum Liquid Discharge (MLD) facility featuring the RO Infinity with CFRO and Free Radical Oxidation (FRO) technologies.

Fast Facts

Location: Mahachai, Thailand

End User: A Swiss-based Gobal Specialty

Chemicals Company

Solution: Zero Liquid Discharge

Industry: Semiconductor

Feedwater Source: Dye Wastewater

Technology: RO Infinity with CFRO, Free Radical Oxidation

System Configuration: 6 stages of RO Infinity CFRO and 1 train of FRO

System Capacity: 1,000 m3 /day

Online Date: November 2023

Delivery Model: Design-Build (DB)

The Challenge

The Swiss-based client is a global leader in dye manufacturing for the world’s leading apparel brands. Their manufacturing plant in Thailand produces a dye wastewater with with high levels of Total Dissolved Solids (TDS) and Chemical Oxygen Demand (COD). The primary challenge was identifying a solution to create a sustainable dye manufacturing process, maximize water reuse, and achieve MLD. With limited cost-effective options for brine minimization, the client looked to partner with Gradiant to achieve its sustainability goals.

The Solution

To treat a variety of feedwater quality and to achieve MLD, Gradiant proposed a robust solution featuring 6 stages of RO Infinity with CFRO and FRO. The CFRO system demonstrated it could concentrate brine recoveries up to 97%. The wastewater was then treated by FRO to remove color by oxidizing the organics. This solution also proved successful to remove high TDS and COD, allowing for the dye wastewater to be reused in the manufacturing process, while saving up to 40% CAPEX compared to Ultra-High Pressure RO (UHPRO).

The Benefits

Gradiant delivered a custom RO Infinity with CFRO system that achieves MLD, as well as beneficial reuse of the wastewater. The process produces fresh water that contains 24 to 48 times less TDS, and can be reused for dye manufacturing. The FRO technology achieves a colorless brine concentrate stream that can be processed as a by-product for salt preparation and resin regeneration. Gradiant’s RO Infinity is used for the primary solution to reduce fouling and scaling.

Impact Stats

24X-48X

TDS reduction after treatment

ZERO

Zero Liquid Discharge

40%

up to 40% CAPEX and OPEX Savings in comparison to UHPRO

50%

up to 50% Cost Savings with CFRO compared to other brine minimization technologies

Figures & Images

Semiconductor Manufacturer’s LSR Process Flow Diagram

Legal Disclaimer

This document is for general information only. No warranty or guarantee whatsoever is given or implied and Gradiant is not bound by or liable for or by the information contained herein. Customer has the sole responsibility to determine whether the information in this document are appropriate for Customer’s use, including without limitation actual site, geographical, and plant conditions, specifications, requirements, disposal, applicable laws and regulations. This document is the intellectual property of Gradiant, including but not limited to any patent or trademark contained in this document. Distribution of this document is not and does not imply any transfer of Gradiant’s intellectual property.

Gradiant, the Gradiant Logo, and all service marks denoted with ™ or ® are owned by affiliates of Gradiant Corporation unless otherwise noted. © 2024 Gradiant.